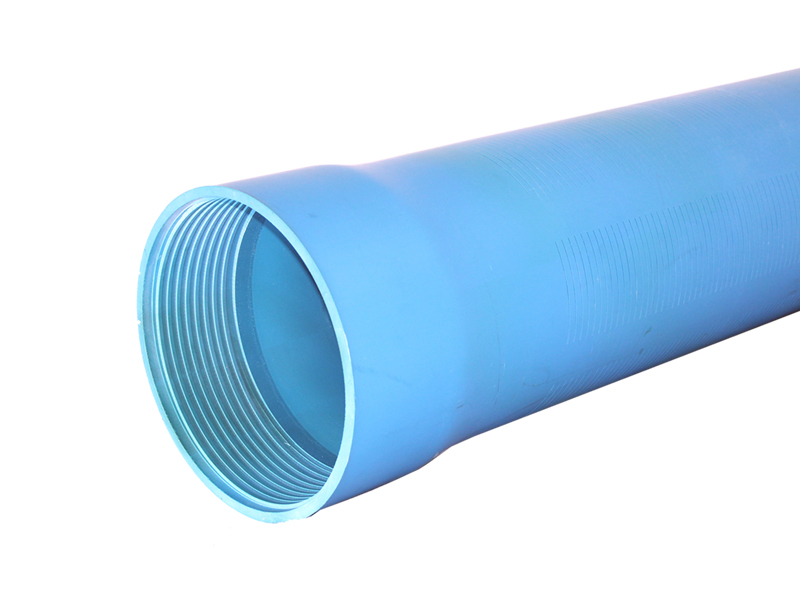

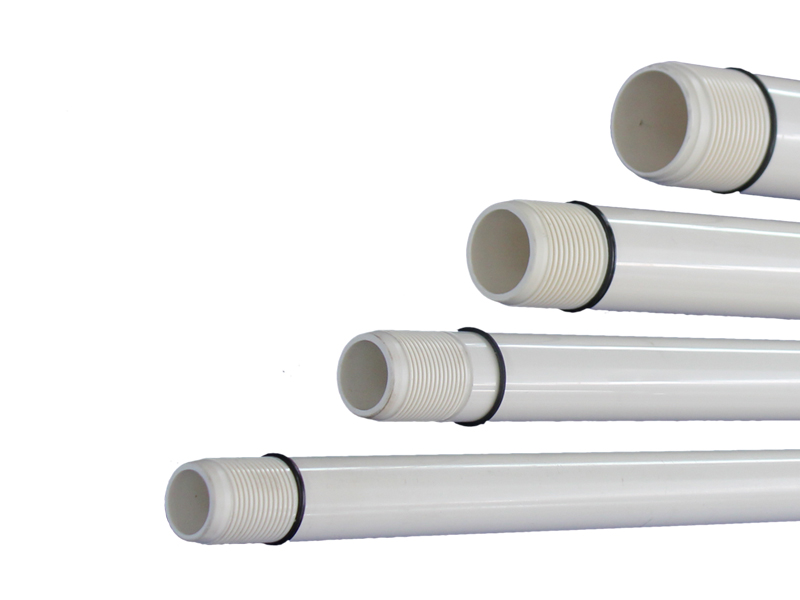

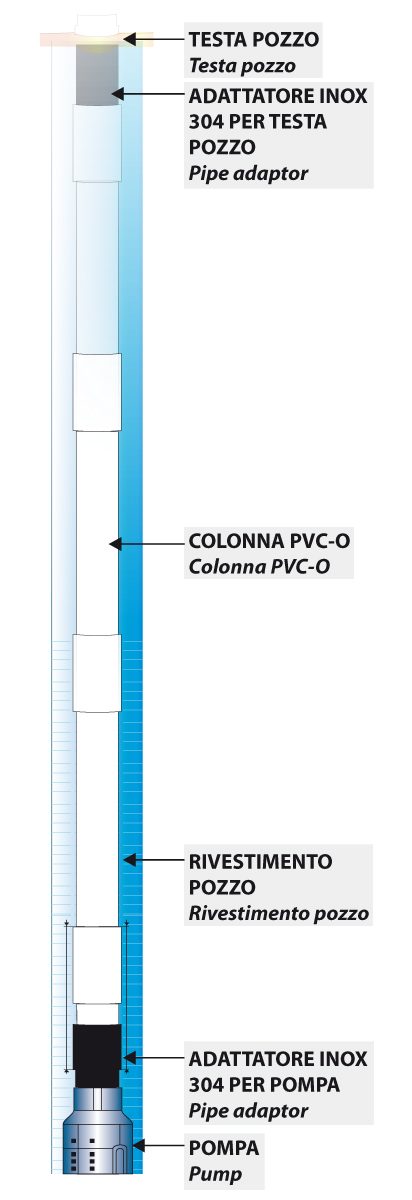

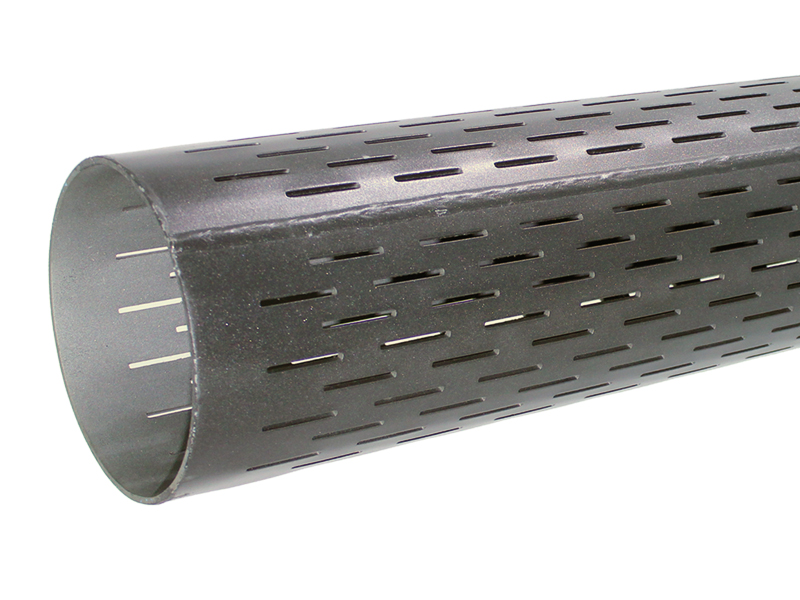

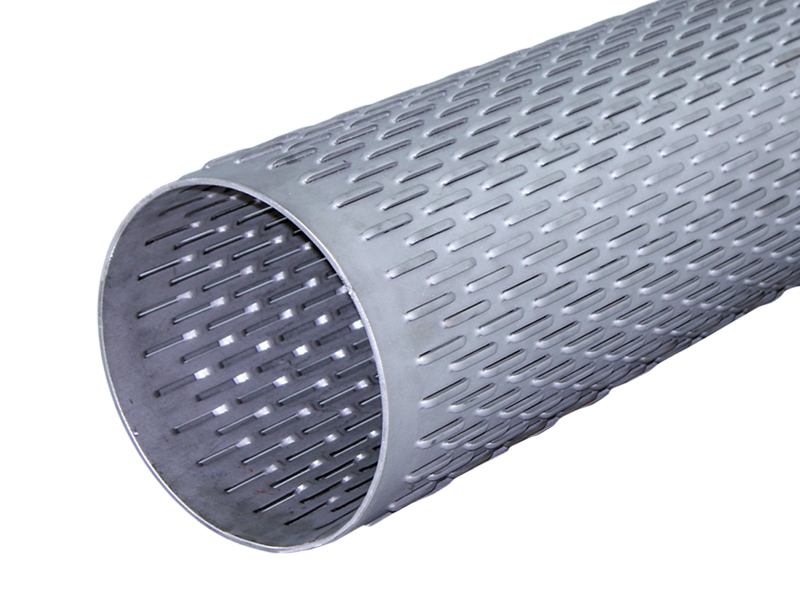

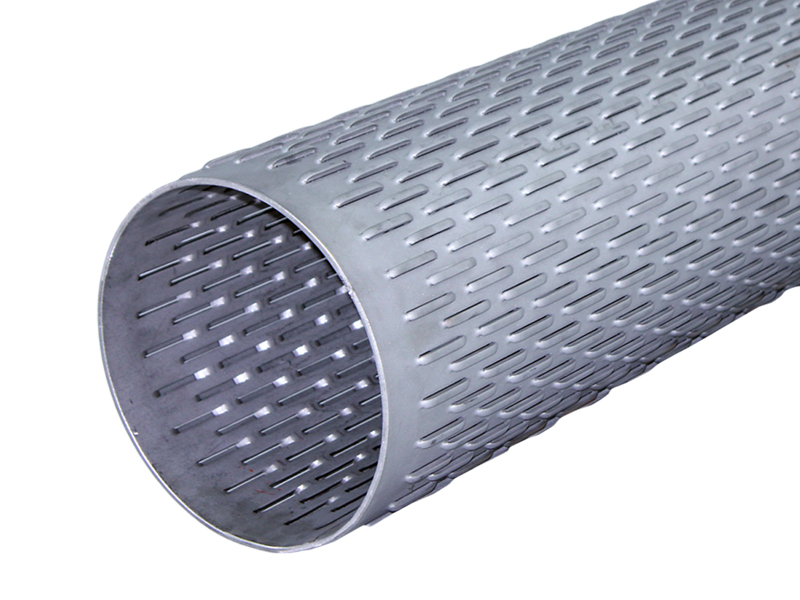

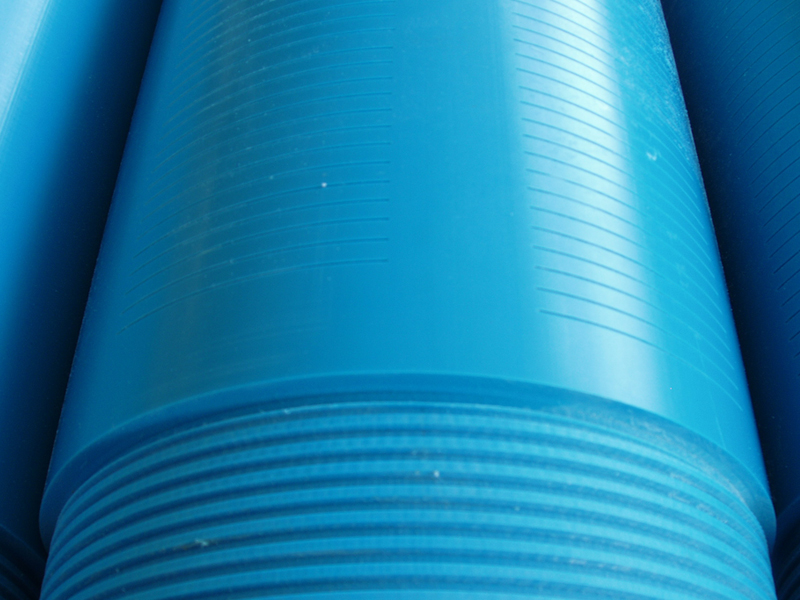

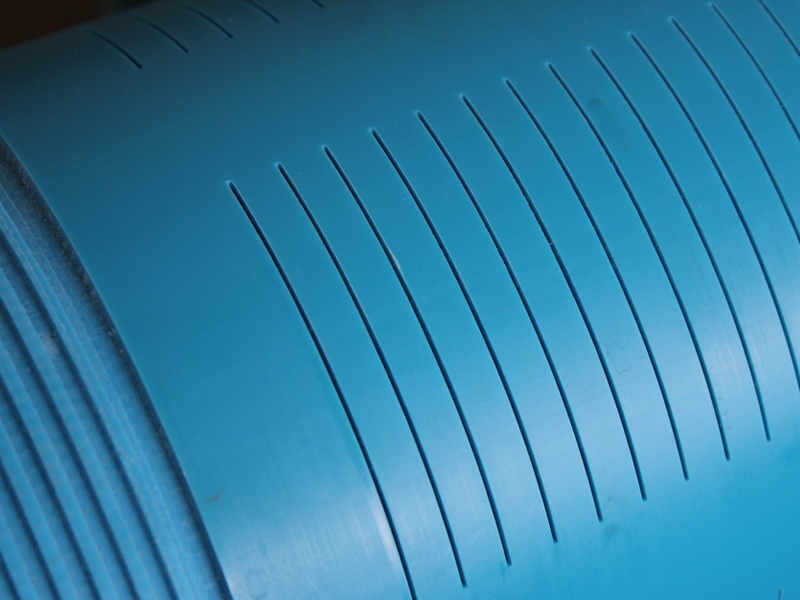

GTS pipe pipes are suitable for the construction of water wells, in particular for small and medium sized wells intended for pumping drinking water.

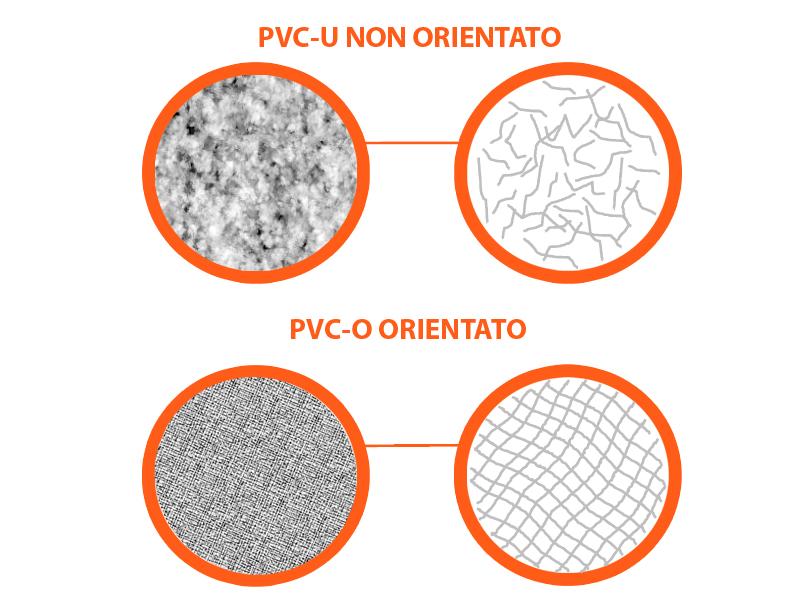

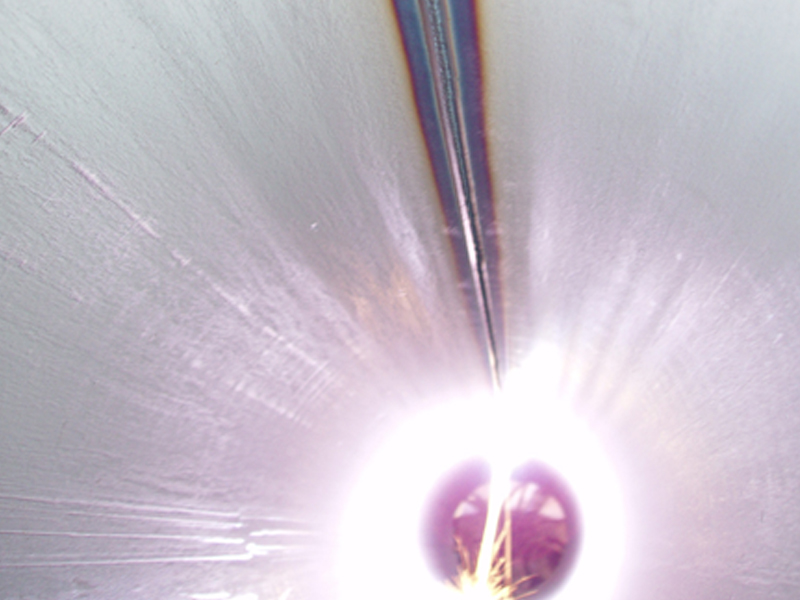

They are made of non-plasticised polyvinylchloride (U-PVC) with specific additives to ensure a high resistance to collapse and traction. The PVC compounds are regularly tested by third-party organisation to ensure their use for prolonged contact with drinking water, in accordance with Ministerial Decree 174-2004 and Reg. EU N.10-2011

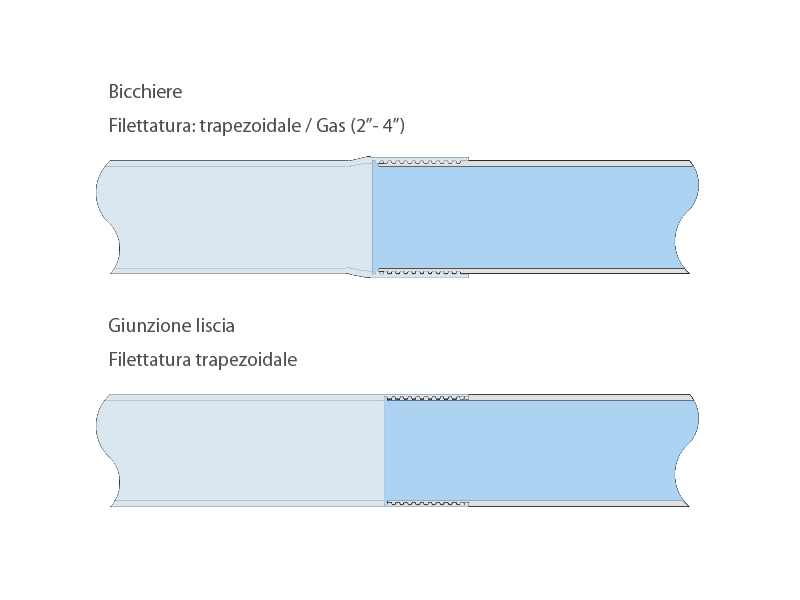

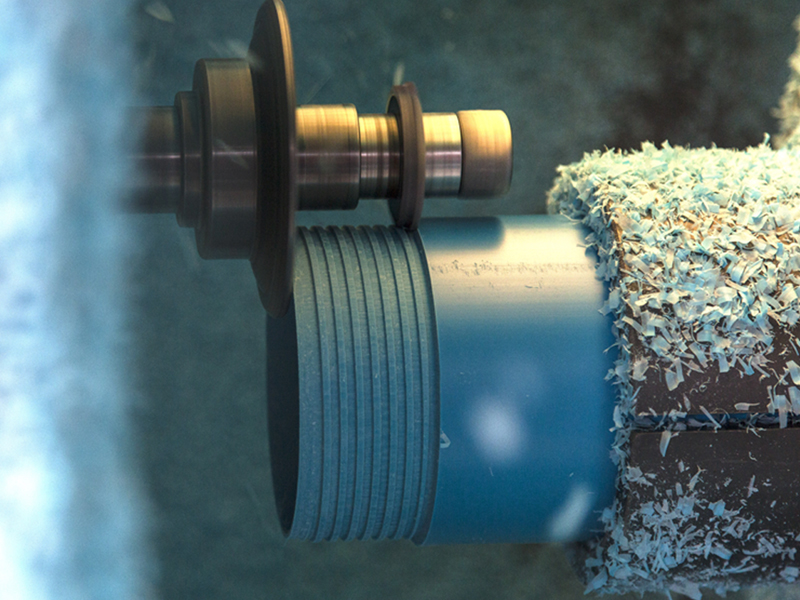

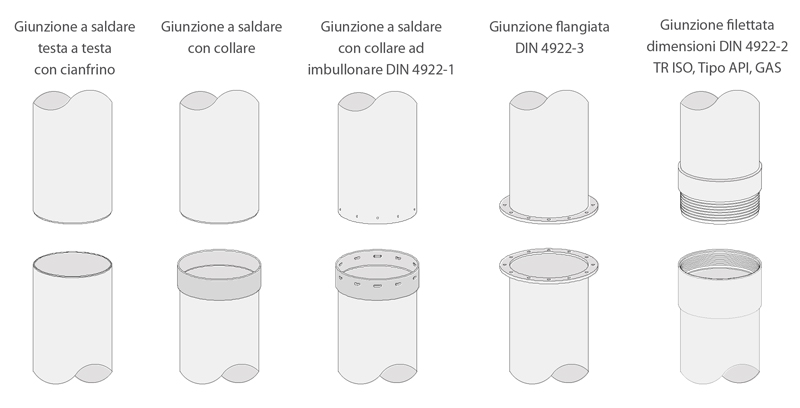

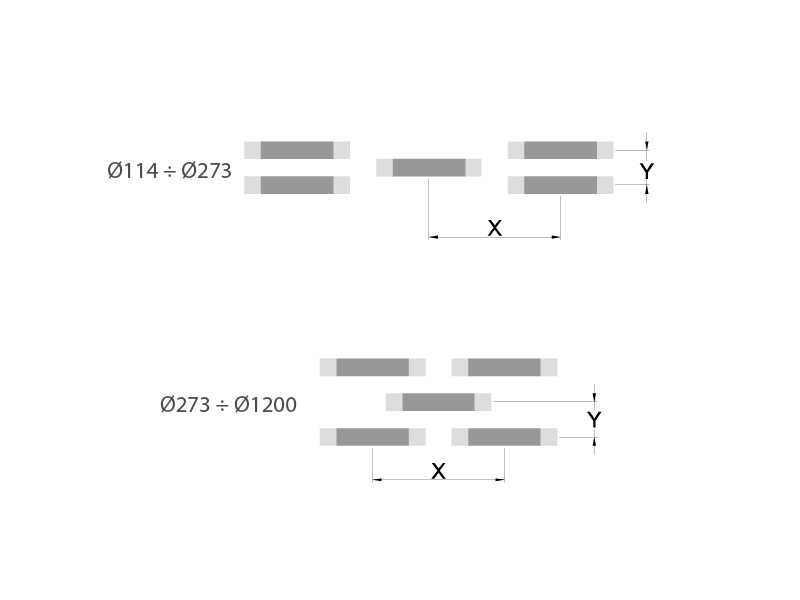

The junctions of the elements are made by trapezoidal M/F threading or Gas in diameters up to 4″ (Ø114). The M/F couplings can be obtained directly in the pipe wall to obtain a smooth junction without external encumbrances, or with the female threading obtained in the end with a glass (larger dimension).

U-PVC mechanical features:

Density: 1.45 ÷ 1.65 g/cm³

Yield strength: 48 Mpa

Elastic module: 3000 Mpa

Hardness: 80 ÷ 84 shore D

Softening temperature – Vicat: 78 °C ÷ 84 °C

| Ø ext (mm) | Ø ext (inch) | series | Ø int (mm) | thickness (mm) | Ø ext. glass (mm) | weight Kg/m | collapse resistance (bar) |

| 60 | 2" | - | 51,6 | 4,2 | 65 | 1,1 | 17,4 |

| 75 | 2" 1/2 | - | 66,0 | 4,5 | 81 | 1,5 | 10,7 |

| 89 | 3" | - | 79,0 | 5,0 | 95 | 2,0 | 8,7 |

| 114 | 4" | - | 103,4 | 5,3 | 120 | 2,7 | 4,9 |

| 125 | - | 115,0 | 5,0 | 130 | 2,8 | 3,1 | |

| 125 | 12.5 | 113,0 | 6,0 | 131 | 3,4 | 5,4 | |

| 125 | 20 | 106,6 | 9,2 | 138 | 5,0 | 20,4 | |

| 140 | 10 | 129,2 | 5,4 | 146 | 3,4 | 2,7 | |

| 140 | 12.5 | 126,6 | 6,7 | 149 | 4,2 | 5,3 | |

| 140 | 20 | 119,4 | 10,3 | 155 | 6,3 | 20,4 | |

| 160 | 10 | 147,6 | 6,2 | 168 | 4,5 | 2,8 | |

| 160 | 12.5 | 144,6 | 7,7 | 170 | 5,5 | 5,4 | |

| 160 | 20 | 136,4 | 11,8 | 178 | 8,2 | 20,6 | |

| 170 | - | 154,8 | 7,6 | 180 | 5,8 | 4,3 | |

| 180 | 10 | 166,2 | 6,9 | 188 | 5,6 | 2,7 | |

| 180 | 12.5 | 162,8 | 8,6 | 191 | 6,9 | 5,3 | |

| 180 | 20 | 153,4 | 13,3 | 201 | 10,4 | 20,7 | |

| 200 | 10 | 184,6 | 7,7 | 210 | 7,0 | 2,7 | |

| 200 | 12.5 | 180,8 | 9,6 | 214 | 8,6 | 5,4 | |

| 200 | 20 | 170,6 | 14,7 | 224 | 12,8 | 20,3 | |

| 225 | 10 | 207,8 | 8,6 | 236 | 8,8 | 2,7 | |

| 225 | 12.5 | 203,4 | 10,8 | 240 | 10,9 | 5,4 | |

| 225 | 20 | 191,8 | 16,6 | 252 | 16,3 | 20,6 | |

| 250 | 10 | 230,8 | 9,6 | 264 | 10,9 | 2,7 | |

| 250 | 12.5 | 226,2 | 11,9 | 268 | 13,4 | 5,2 | |

| 250 | 20 | 213,2 | 18,4 | 280 | 20,1 | 20,4 | |

| 280 | 10 | 258,6 | 10,7 | 298 | 13,6 | 2,7 | |

| 280 | 12.5 | 253,2 | 13,4 | 302 | 16,8 | 5,3 | |

| 280 | - | 248,0 | 16,0 | 309 | 19,9 | 9,2 | |

| 315 | 10 | 290,8 | 12,1 | 330 | 17,3 | 2,7 | |

| 315 | 12.5 | 285,0 | 15,0 | 335 | 21,2 | 5,2 | |

| 330 | - | 301,0 | 14,5 | 353 | 21,6 | 4,1 | |

| 330 | - | 292,0 | 19,0 | 362 | 27,8 | 9,4 | |

| 400 | - | 376,6 | 11,7 | 415 | 21,4 | 1,2 | |

| 400 | 10 | 369,4 | 15,3 | 422 | 27,7 | 2,7 | |

| 400 | 12.5 | 361,8 | 19,1 | 430 | 34,3 | 5,3 | |

| 450 | 10 | 415,6 | 17,2 | 475 | 35,1 | 2,7 | |

| 450 | 12.5 | 407,0 | 21,5 | 483 | 43,4 | 5,3 | |

| 500 | 10 | 461,8 | 19,1 | 528 | 43,3 | 2,6 | |

| 630 | - | 591,8 | 19,1 | 660 | 55,0 | 1,3 |

Download the brochure with the product technical data sheets

Benefits

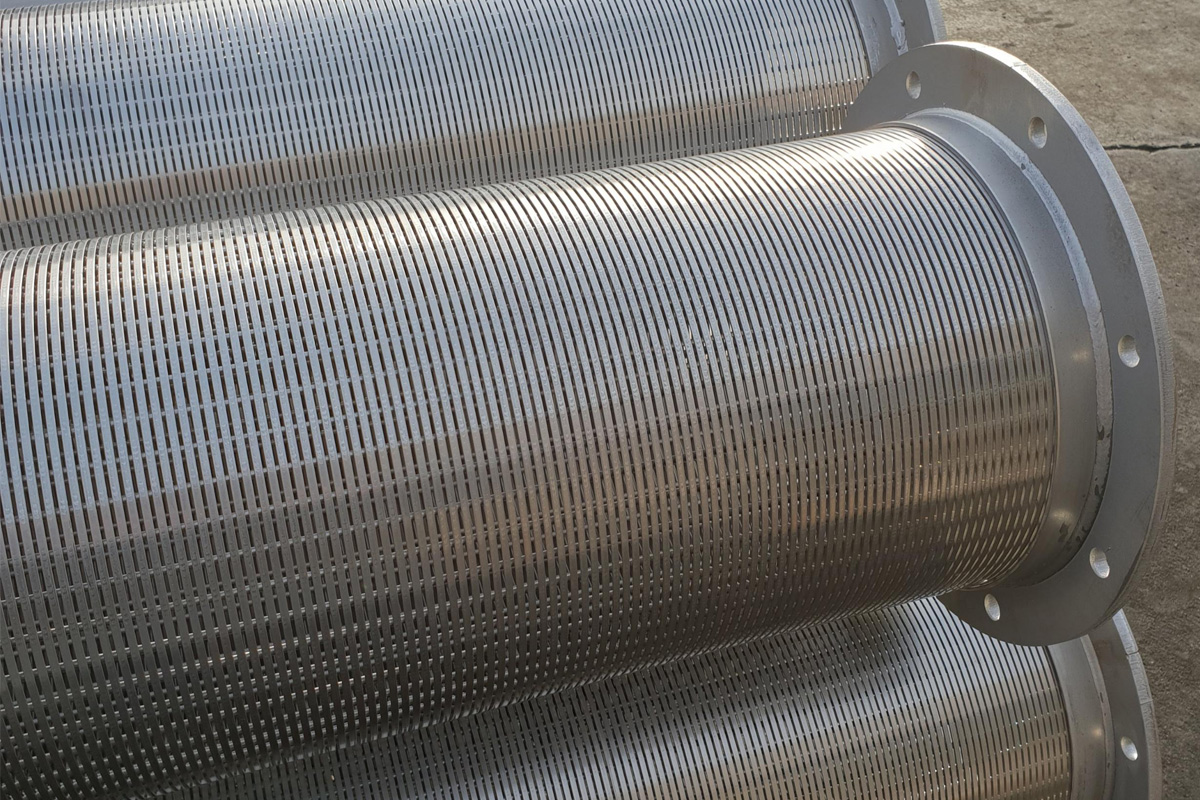

High corrosion resistance

High durability

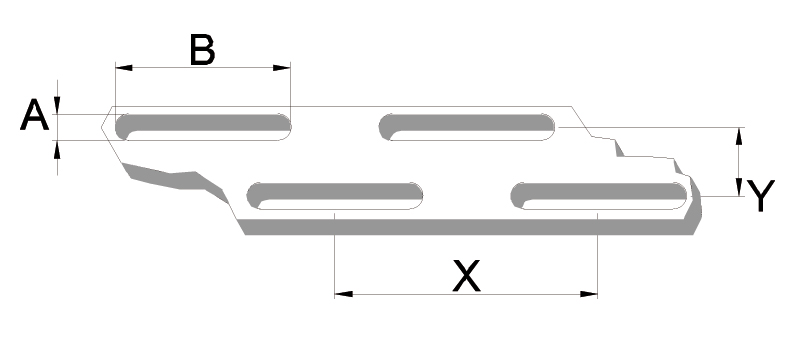

Adaptability to the granulometric curve