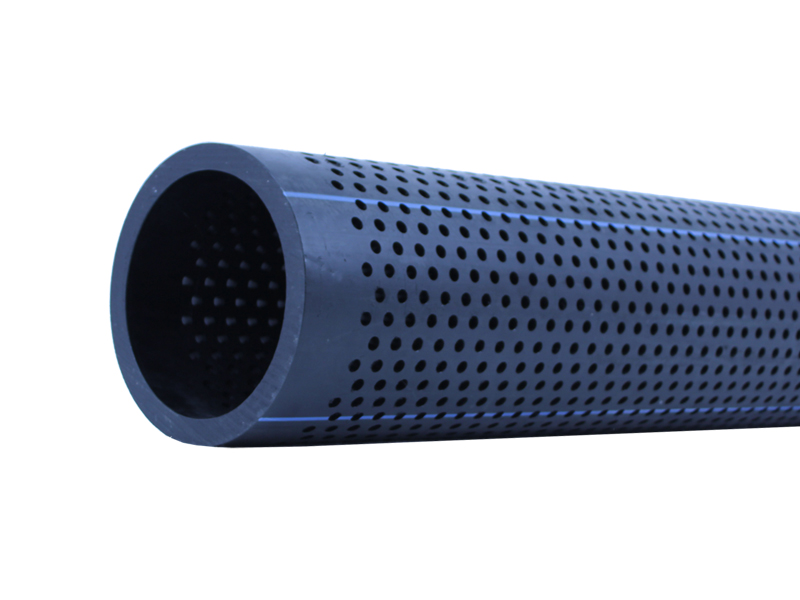

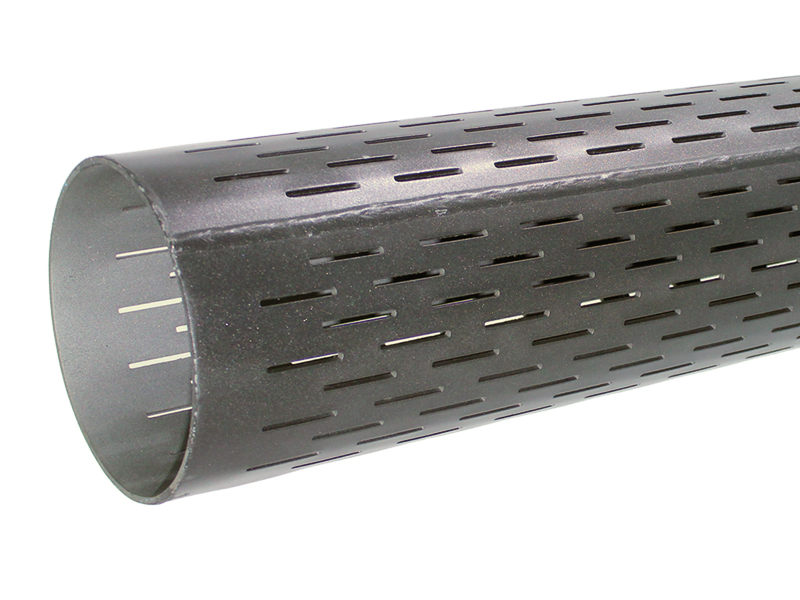

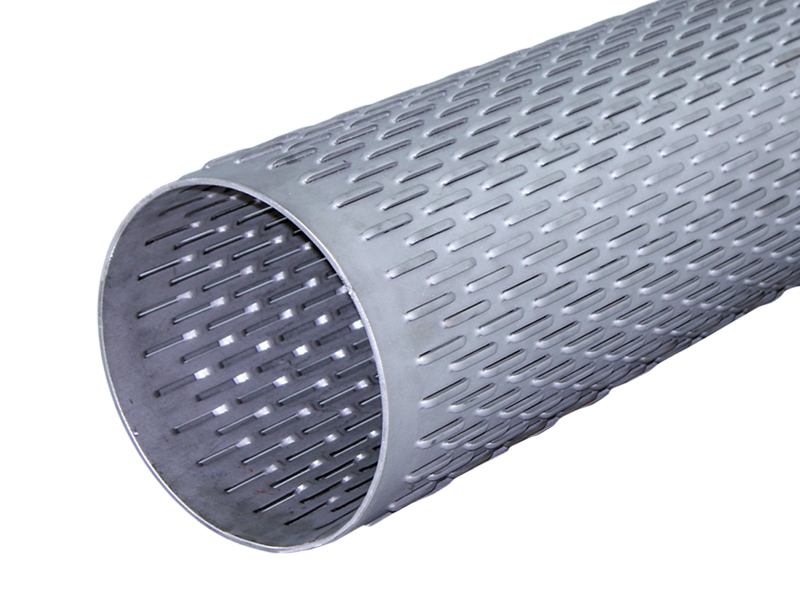

I tubi e filtri in polietilene ad alta densità sono indicati per le applicazioni dove le condizioni dei terreni risultano corrosive e particolarmente aggressive quali ad esempio i siti contaminati e le discariche.

The high-density polyethylene pipes and filters are suitable for applications where soil conditions are corrosive and particularly aggressive, such as contaminated sites and landfills.

High-density polyethylene HDPE features:

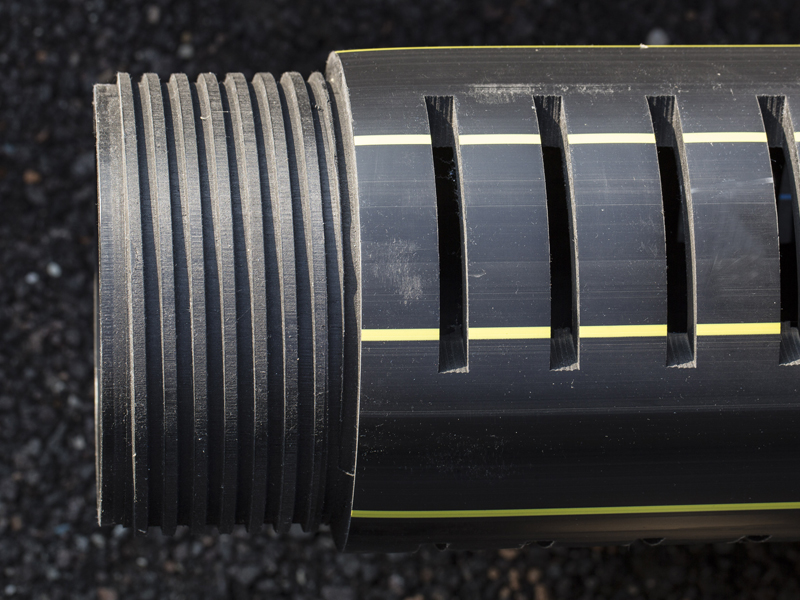

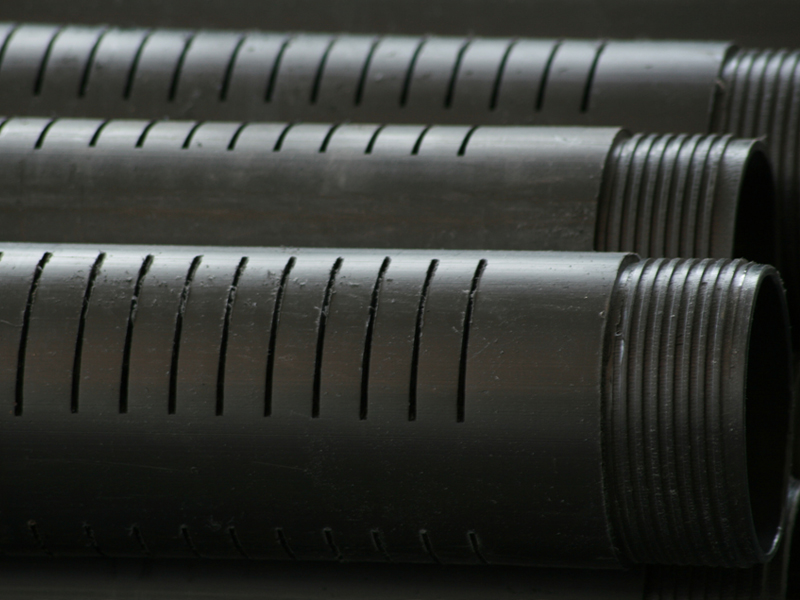

Colour: black with blue or yellow co-extruded line

Density: 950 kg / m3

Yield strength: 21 MPa

Elongation at breakage:> 350%

Elasticity module: 850 MPa

Reference standards:

PE100: UNI EN 12201 – ISO 4427 – UNI EN ISO 15494

PE 80 : EN1555 – ISO 4437

SERIES PE100

PN6 SDR26

| DN* | th (mm) | Inside diameter | Weight |

| 63 | - | - | - |

| 75 | - | - | - |

| 90 | - | - | - |

| 110 | - | - | - |

| 125 | - | - | - |

| 140 | - | - | - |

| 160 | 6,2 | 147,6 | 2,85 |

| 180 | 6,9 | 166,2 | 3,56 |

| 200 | 7,7 | 184,6 | 4,42 |

| 225 | 8,6 | 207,8 | 5,55 |

| 250 | 9,6 | 230,8 | 6,89 |

| 280 | 10,7 | 258,6 | 8,60 |

| 315 | 12,1 | 290,8 | 10,94 |

| 355 | 13,6 | 327,8 | 13,86 |

| 400 | 15,3 | 369,4 | 17,57 |

| 450 | 17,2 | 415,6 | 22,22 |

| 500 | 19,1 | 461,8 | 27,41 |

| 560 | 21,4 | 517,2 | 34,40 |

| 630 | 24,1 | 581,8 | 43,58 |

| 710 | 27,2 | 655,6 | 55,43 |

| 800 | 30,6 | 738,8 | 70,27 |

PN10 SDR17

| DN* | th (mm) | Inside diameter | Weight |

| 63 | 3,8 | 55,4 | 0,67 |

| 75 | 4,5 | 66 | 0,95 |

| 90 | 5,4 | 79,2 | 1,36 |

| 110 | 6,6 | 96,8 | 2,04 |

| 125 | 7,4 | 110,2 | 2,60 |

| 140 | 8,3 | 123,4 | 3,26 |

| 160 | 9,5 | 141 | 4,27 |

| 180 | 10,7 | 158,6 | 5,41 |

| 200 | 11,9 | 176,2 | 6,68 |

| 225 | 13,4 | 198,2 | 8,46 |

| 250 | 14,8 | 220,4 | 10,39 |

| 280 | 16,6 | 246,8 | 13,05 |

| 315 | 18,7 | 277,6 | 16,54 |

| 355 | 21,1 | 312,8 | 21,03 |

| 400 | 23,7 | 352,6 | 26,62 |

| 450 | 26,7 | 396,6 | 33,73 |

| 500 | 29,7 | 440,6 | 41,69 |

| 560 | 33,2 | 493,6 | 52,20 |

| 630 | 37,4 | 555,2 | 66,15 |

| 710 | 42,1 | 625,8 | 83,92 |

| 800 | 47,4 | 705,2 | 106,47 |

PN16 SDR11

| DN* | th (mm) | Inside diameter | Weight |

| 63 | 5,8 | 51,4 | 0,99 |

| 75 | 6,8 | 61,4 | 1,38 |

| 90 | 8,2 | 73,6 | 2,00 |

| 110 | 10 | 90 | 2,98 |

| 125 | 11,4 | 102,2 | 3,87 |

| 140 | 12,7 | 114,6 | 4,83 |

| 160 | 14,6 | 130,8 | 6,34 |

| 180 | 16,4 | 147,2 | 8,01 |

| 200 | 18,2 | 163,6 | 9,88 |

| 225 | 20,5 | 184 | 12,51 |

| 250 | 22,7 | 204,6 | 15,40 |

| 280 | 25,4 | 229,2 | 19,30 |

| 315 | 28,6 | 257,8 | 24,45 |

| 355 | 32,2 | 290,6 | 31,02 |

| 400 | 36,3 | 327,4 | 39,40 |

| 450 | 40,9 | 368,2 | 49,94 |

| 500 | 45,4 | 409,2 | 61,60 |

| 560 | 50,8 | 458,4 | 77,20 |

| 630 | 57,2 | 515,6 | 97,79 |

| 710 | - | - | - |

| 800 | - | - | - |

PN25 SDR7,4

| DN* | th(mm) | Inside diameter | Weight |

| 63 | 8,6 | 45,8 | 1,40 |

| 75 | 10,3 | 54,4 | 1,99 |

| 90 | 12,3 | 65,4 | 2,85 |

| 110 | 15,1 | 79,8 | 4,28 |

| 125 | 17,1 | 90,8 | 5,51 |

| 140 | 19,2 | 101,6 | 6,92 |

| 160 | 21,9 | 116,2 | 9,03 |

| 180 | 24,6 | 130,8 | 11,41 |

| 200 | 27,4 | 145,2 | 14,11 |

| 225 | 30,8 | 163,4 | 17,85 |

| 250 | 34,2 | 181,6 | 22,03 |

| 280 | 38,3 | 203,4 | 27,63 |

| 315 | 43,1 | 228,8 | 34,98 |

| 355 | 48,5 | 258 | 44,37 |

| 400 | 54,7 | 290,6 | 56,37 |

| 450 | 61,5 | 327 | 71,31 |

| 500 | - | - | - |

| 560 | - | - | - |

| 630 | - | - | - |

| 710 | - | - | - |

| 800 | - | - | - |

SERIES PE80 (gas)

S5 SDR 11

| DN | th (mm) | Inside diameter (mm) | Weight (Kg/m) |

| 63 | 3,6 | 55,8 | 0,64 |

| 75 | 4,3 | 66,4 | 0,91 |

| 90 | 5,2 | 79,6 | 1,32 |

| 110 | 6,3 | 97,4 | 1,95 |

| 125 | 7,1 | 110,8 | 2,50 |

| 140 | 8 | 124 | 3,15 |

| 160 | 9,1 | 141,8 | 4,10 |

| 180 | 10,3 | 159,4 | 5,22 |

| 200 | 11,4 | 177,2 | 6,42 |

| 225 | 12,8 | 199,4 | 8,11 |

| 250 | 14,2 | 221,6 | 9,99 |

| 280 | 16 | 248 | 12,61 |

| 315 | 17,9 | 279,2 | 15,87 |

| 355 | 20,5 | 314 | 20,47 |

| 400 | 22,8 | 354,4 | 25,67 |

S5 SDR 11

| DN | th (mm) | Inside diameter (mm) | Weight (Kg/m) |

| 63 | 5,8 | 51,4 | 0,99 |

| 75 | 6,8 | 61,4 | 1,38 |

| 90 | 8,2 | 73,6 | 2,00 |

| 110 | 10 | 90 | 2,98 |

| 125 | 11,4 | 102,2 | 3,87 |

| 140 | 12,7 | 114,6 | 4,83 |

| 160 | 14,6 | 130,8 | 6,34 |

| 180 | 16,4 | 147,2 | 8,01 |

| 200 | 18,2 | 163,6 | 9,88 |

| 225 | 20,5 | 184 | 12,51 |

| 250 | 22,7 | 204,6 | 15,40 |

| 280 | 25,4 | 229,2 | 19,30 |

| 315 | 28,6 | 257,8 | 24,45 |

| 355 | 32,2 | 290,6 | 31,02 |

| 400 | 36,3 | 327,4 | 39,40 |

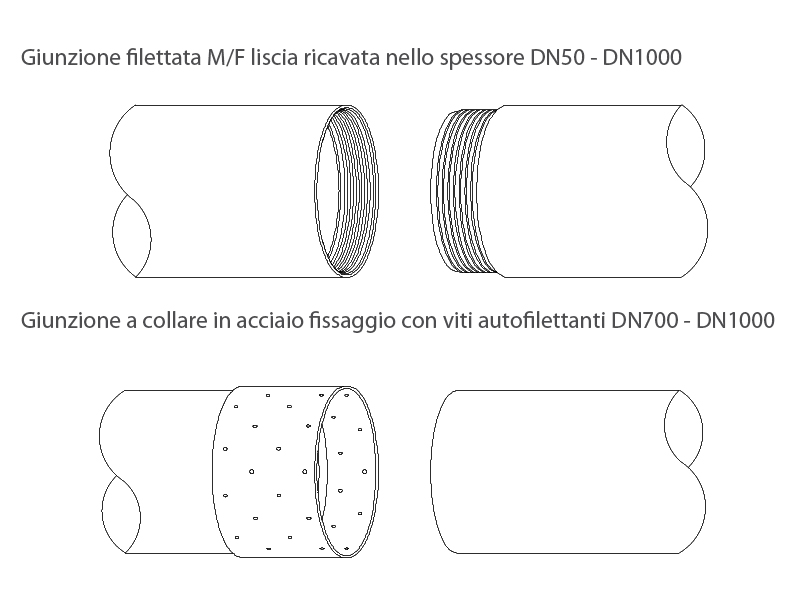

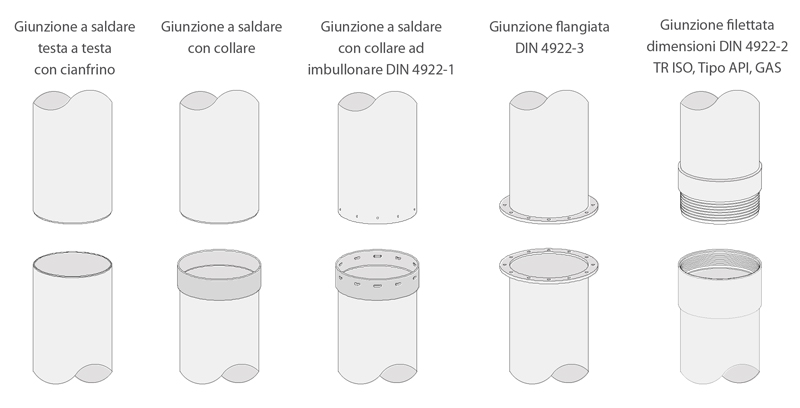

Smooth threaded M/F junction obtained in the DN50-DN1000 thickness

Collar junction in steel fastening with self-threading screws DN700-DN1000

Download the brochure with the product technical data sheets

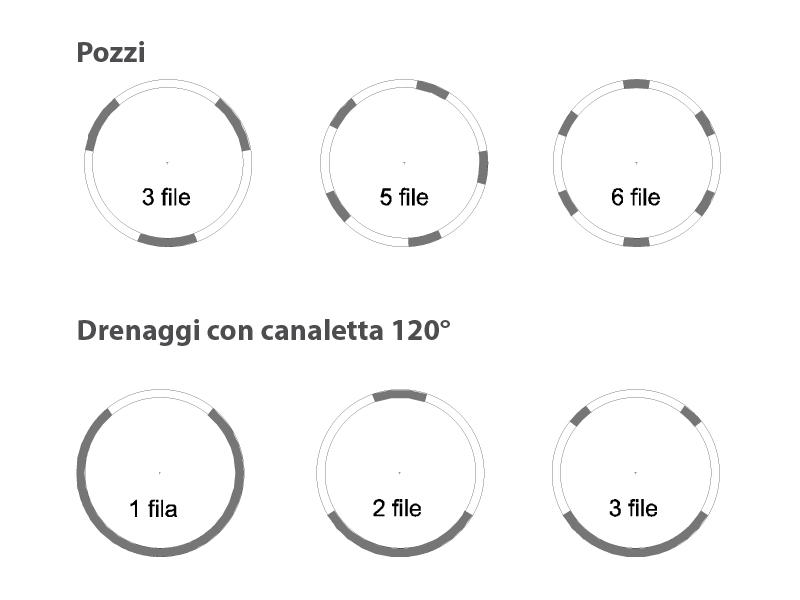

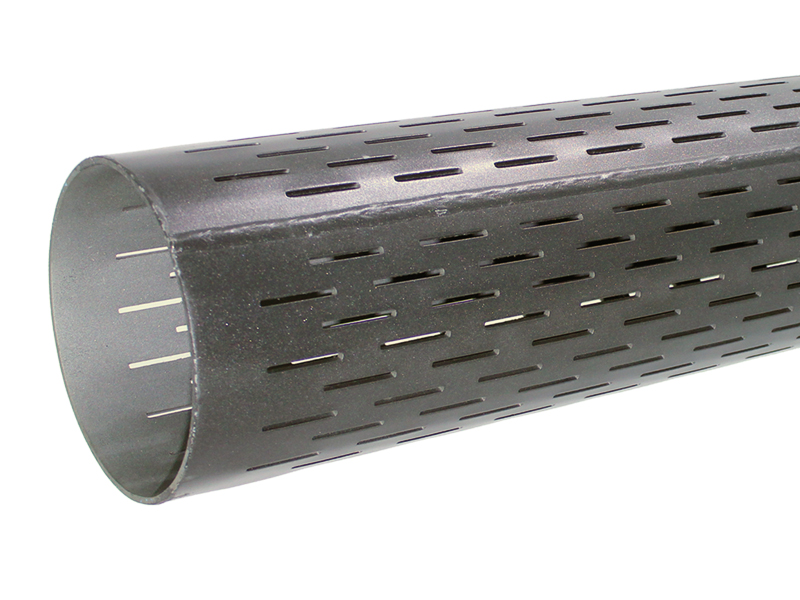

APPLICATIONS

Environmental reclamation and drainage

Reception of biogas from landfill

Leachate collection from landfill